Our Technologies

ANDI aims to be on the leading edge of non-destructive technologies by continually evaluating and incorporating emerging technologies, and seeking new applications for existing ones.

How we do it

Utility Detection Systems

- Detection & Mapping

(Rigid Systems) - Cable Fault Finding

- Locating & Marking

(3M Specialized Systems)

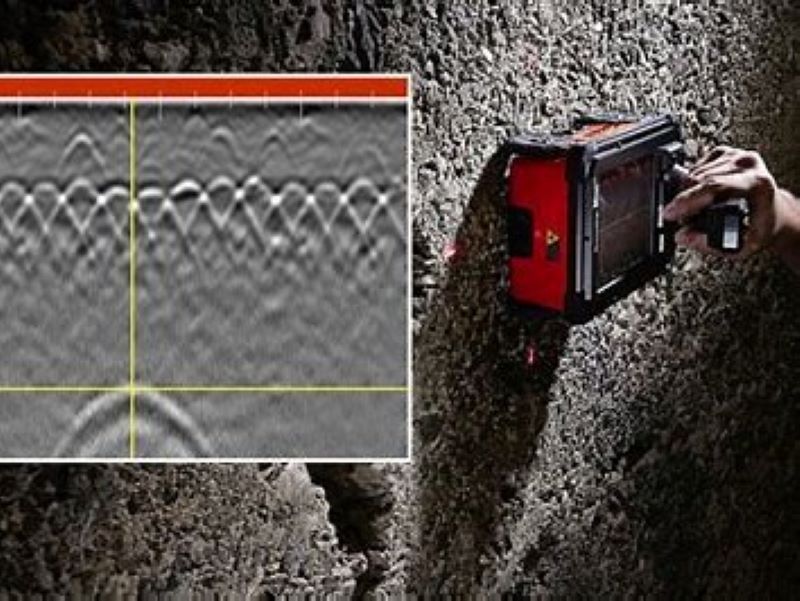

Ground Penetrating Radar (GPR)

ANDI uses the GSSI complete ground penetrating radar (GPR) system for its concrete scanning and masonry inspections, ensuring that we are backed by the highest quality GPR equipment available. These scanners offer superior target resolution and are ideal for locating rebar, conduits, post-tension cables, voids and slab thickness.

Enhanced Data Visualization

The StructureScan systems allows quick effect data collection and offers intuitive data visualization in 2D or 3D displays

Rugged and Flexible

This system is sturdy enough to withstand the toughest conditions and compact enough to work in tight spaces.

Many Applications

Typical uses include: concrete and masonry inspection, structure inspection, condition assessment, slab thickness assessment and void location mapping.

Utility Detection

ANDI offers two distinct but related utility detection services that use different tools, methods and resources.

- Detection and Mapping (Rigid utility detection system)

- Locating and Marking (3M specialized locating and marking system)

Utility Detection – Detection and Mapping

ANDI’s utility detection and mapping uses the Rigid line of locating equipment made to meet the demanding needs of location teams. The Line Locator is one of the tools used by our trained staff to provide utility detection services like mapping underground utilities including buried electrical cables, PVC pipe, metal pipes and more.

Accuracy

Multiple underground lines and congested areas can cause signal distortion and make it difficult to get an accurate locate. The SR-20,

allows trained users to see distortion and improve accuracy through a variety of tools, search mode and signal verifications.

Better Information - More Confidence

Missing a mark can be costly. Accurate mapping of branch lines and even lines you didn’t know existed helps our technicians provide you with information you can count on every time.

Fast and Clear

Four distinct locate indicators ensure the ability to determine a good signal and continually verify the quality of the locate to ensure certainty, immediately record changes in line direction, identify lines from multiple directions and continually record depty and current.

Cable Fault Finding

Advanced Non-Destructive Inc. (ANDI) Cable Fault Finding service identifies electrical faults in underground electrical cables. Using a transmitter to put a dedicated signal on a suspected ground fault cable, the ANDI team will trace the cable path to quickly and efficiently locate conductor and sheath (earth return) faults and estimate the depth of the cable/fault. We will mark any located fault with paint and/or flags to show you exactly where to dig. The process can be applied to cable runs of any length.

Our Cable Fault Finding service identifies the precise location of the fault. Save time and money by only digging where you need. Know the cable depth to better dig safely with less potential for cable damage.

Cable Fault Finding Frame

Non-destructive technician locating a subsurface ground fault

Utility Detection – Locating and Marking

Advanced Non-Destructive Inc. (ANDI) has been offering utility detection services for many years using the top-of-the-line Ridgid utility detection system, which is reliable and accurate in utility location. However, not even the most advanced utility detection systems can directly detect non-conductive materials (e.g. PVC, concrete, or fiberglass), non-energized power lines or low power equipment (e.g. communication lines, and 12V/24V systems). Environmental, utility depth and shielding, and many other conditions can also hamper utility detection. Even placing a trace signal on known conductive utilities can be challenging or impossible at times. The fact is, the technician can only mark/map a tracible signal.

ANDI has upgraded its professional utility detection services and can now offer its clients a solution to these problems to those challenges through the addition of 3M Specialized Locating and Marking Systems, the latest in utility detection advanced technology.

ANDI and 3M will provide you with specialized marker system tape, balls, and tags that are buried with the utilities, it’s as simple as that. Using 3M’s advanced receiver these marker systems can be easily detected many years into the future. Bury it and forget it until you need to know the utility location and ANDI can quickly and accurately locate it for you.

The marking systems are environmentally sealed and do not require batteries. The 3M receiver also acts as a transmitter for these marker systems. The markers are excited by the transmitted signal and the markers are activated and detectable. These marker systems can be buried from near the surface (2’), 4’-5’ (mid range) and up to 8’ (full range). These markers can come in both programable and non-programable (passive) options.

- A revolutionary approach to utility detection for all utilities

- Accurate and rapid utility detection

- Specialized marker systems for different depths and systems

- Detection for non-conductive (metallic) materials (PVC, concrete, data, etc.)

- For long-run utilities or even just single points of interest

- Markers are buried with the utilities for long-term detection (2’-8’)

- Passive and programable marker options

- Systems are tough, long-lasting, do not require any power, and are reusable

Learn More about our Utilities Detection – Locating and Marking

Read more on ANDI’s 3M Specialized Locating and Marking page – or click on any of the options below to jump directly to a specific area of interest.

Visit our 3M Specialized Locating and Marking System to decide which products are right for you.

Infrared Thermal Imaging

ANDI uses infrared thermal imaging for our thermography services. Infrared sensing is fast, reliable, accurate, non-destructive and non-contact. It is used to test electrical systems, mechanical applications, pipe tracing and diagnostic services, building assessment, water infiltration and more.

ANDI has advanced equipment and reporting software plus experience in diverse environments, Others may offer cheaper services but they often use lower quality equipment or equipment that is not right for your application. Contact us to discuss your project and its specific needs. We will ensure high-quality assessment and professional reports with comprehensive results.

Specialized Infrared Cameras

We use FLIR professional series high-resolution thermal imaging camera, specifically designed for thermal imaging professionals. These high-level cameras are precise, flexible, reliable and have internal functions not present in cheaper thermal imaging cameras. They are designed to work in diverse environments providing quality results for the seasoned result-orientated professional.

ANDI also uses FLIR advanced reporting software for professional-level reporting. Our thermal imaging equipment is calibrated annually by Flir’s calibration service in Ontario. The calibration certificate is provided with every report to provide additional assurance to accuracy.

Rapid Analysis

High-performance thermal imaging equipment provides accurate temperature measurement for rapid analysis of structural, electrical, marine (ships) and mechanical applications. Our professional-level camera lets us provide comprehensive image analysis onsite. This allows rapid response capabilities and corrections to critical or near critical situations to prevent costly downtimes.

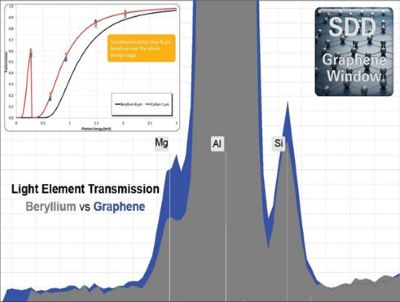

X-Ray Fluorescence (XRF) – XRF Equipment

ANDI’s trained technicians use X-Ray Fluorescence – XRF Analysis Equipment for our positive material identification (PMI) services, which offer non-destructive analysis allowing us to provide you with a comprehensive material identification report of alloy element concentrates.

Our PMI operators ensure that X-ray tests are completed in compliance with all federal and provincial (NL) XRF safety standards for the safety of the operator and of our client’s employees and customers.

Reliability

A Positive Material Identification (PMI) and verification program can help reduce or eliminate costly alloy mix-ups. Our X-Ray Fluorescence tools provide alloy component reliability and traceability.

Graphene windows increase the analyzer’s sensitivity to key light alloy elements such as magnesium (Mg), aluminum (Al), silicon (Si), and even phosphorus (P) and sulfur (S). Detects magnesium (Mg) faster, achieved lower limits of detection for aluminum (Al) in nickel alloy, measures silicon (Si) under 1000 ppm in low-alloy steels faster and with better precision, and measures phosphorus (P) and sulfur (S) in low-alloy steels below 0.035%.

Safety

In refinery or other industries requiring high temperature and high pressure, safety is routinely ensured by verifying that a give n allow conforms to design specifications. A significant number of incidents in refineries and chemical plants are caused by having the wrong metal in service. A strong PMI program supported by X-Ray Fluorescence can virtually eliminate these errors.

Tracability

On the manufacturing floor or in a machine shop, alloy identification might but lost when metal is moved through the shop. Using an X-Ray Fluorescence analyzer allows fast recovery of lost material traceability and ensures the correct material before a costly error.

Contact Us

Advanced Non-Destructive Inc. (ANDI)

ANDI invests in the latest in non-destructive technologies

– for today AND for the future.